An second impregnation plant was sent to China, after the first delivered and installed in 2019.

A multi-treatment plant

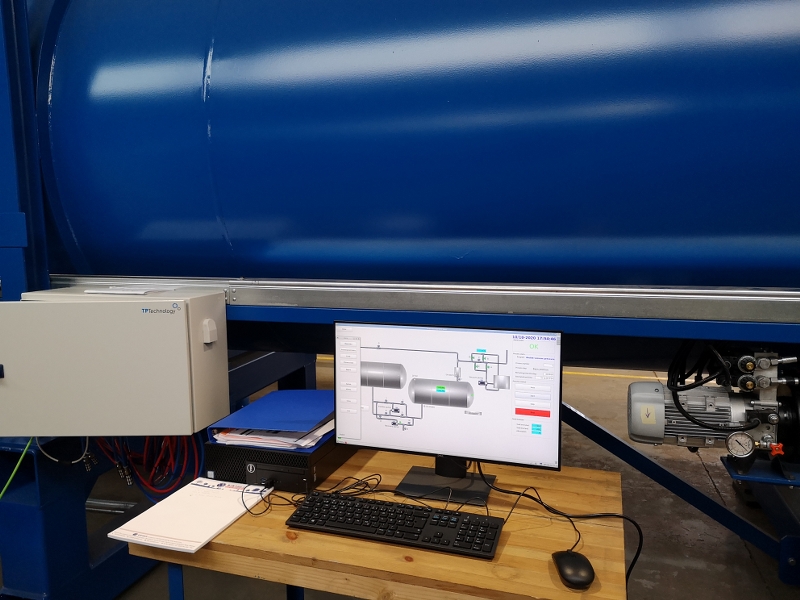

It is a system with a high concentration of technology, but equipped with an intuitive and at the same time complete control system.

The control software records the treatment cycles, releasing a diagram and a report with the data for each cycle. One of the fundamental data is the absorption (liters/m3) of preservative.

The wood can be subjected to various treatment cycles, for example: Rüping, multi-vacuum, double-vacuum and pressure.

Specifically, the plant at the customer's premises will carry out LOSP impregnation treatments.

The LOSP treatment

The name LOSP identifies a solvent based treatment, which contains fungicides and insecticides.

The wood is impregnated with "eco-frendly" preservatives, i.e. low environmental impact 🌱 which guarantee resistance to the attack of termites and fungi.

It is used for the treatment of wooden structures up to use class 3, i.e. where the wood is outside but not in contact with the ground.

The key advantage of the LOSP treatment process is that it does not cause any change in moisture content, size or structural classification of wood products.

For this reason it is ideal for the treatment of wood products that are finished in size, with tight tolerances, such as window frames, cladding and cladding panels. Likewise, it is also ideal for structural or engineered timber products (such as LVL and glulam products) that rely on a low moisture content for structural classification.