WWe delivered a vacuum plate dryer to a major Slovenian company.

Our customer's company represents a leading company in the field of wooden houses and high quality furniture.

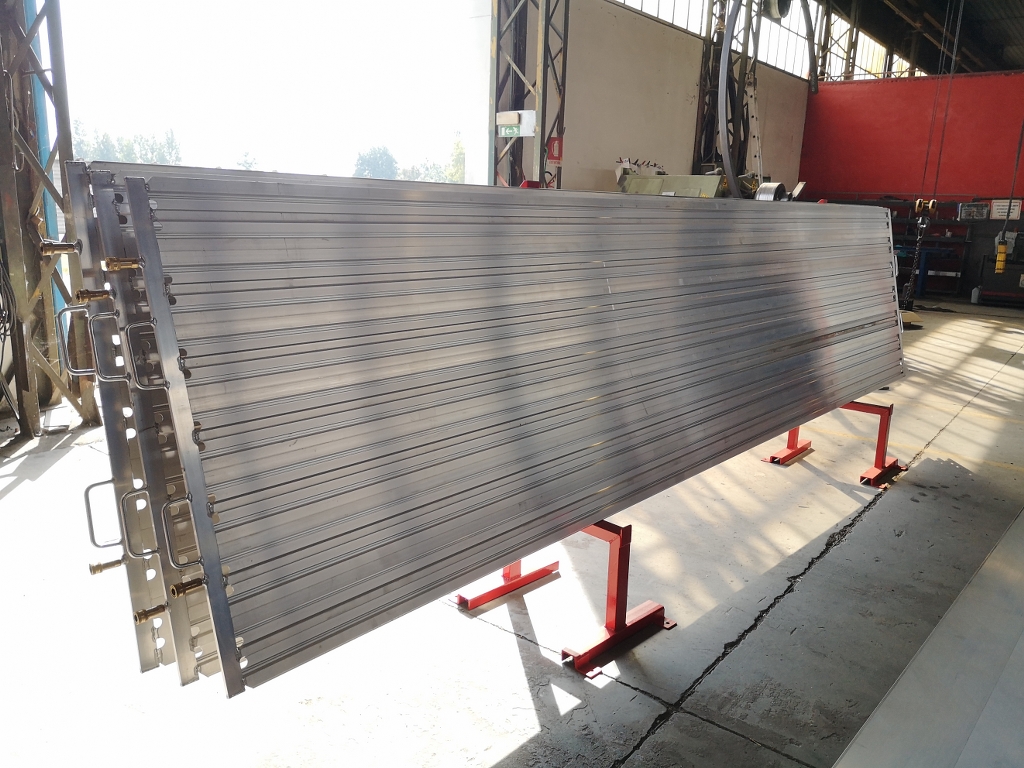

Plate vacuum dryer

The model purchased by the customer is the ESP model, which is a hot plate dryer with continuous vacuum operation.

The use of heating plates in direct contact with the wood and the use of a continuous vacuum, allow to obtain the best results in terms of speed and quality of drying.

An ecological alternative 🌱 to cement

Thanks to the transverse orientation of each of its longitudinal and transverse layers, the degrees of contraction and expansion of the wood at board level are reduced to a negligible amount, while the static load and stability are significantly improved.

Concrete, an essential building material, has for decades offered us the opportunity to shape our cities quickly and effectively, allowing them to expand rapidly in the urban periphery and reach heights unimaginable by man. Today, new wood technologies are beginning to offer similar - and even greater - opportunities through materials such as cross-laminated timber (CLT).

The trace left in the environment by concrete is enormous compared to that of wood. One tonne of CO2 is emitted into the atmosphere for every cubic metre of cement produced. In contrast, CLT contains "sequestered carbon" or carbon stored naturally in the wood during tree growth. Therefore, despite all the energy used in the extraction and production processes, the emissions from wooden buildings will never reach the amount of carbon that is "sequestered" in CLT.